MODEL:VCBS-4F

Designed and manufactured by FORRICH the new generation of NC Servo Fully Automatic Veneer Core Builder is suitable for composing veneer thickness from 1.5mm to 4.0mm. The machine provides high feed speed up to 31 meters per minute. The entire motion sequences from material infeed to product stacking are fully automatic operated.

Another important feature is the cutting system employs servo motor drive to replace the conventional clutch brake control. This feature enables FORRICH VCBS-4F to thoroughly presents its outstanding cutting stability and accuracy. Another benefit is the material loss percentage is reduced to a minimum.

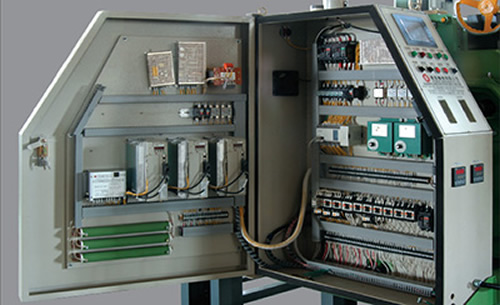

This machine is equipped with a PLC control combined with touch-sensing screen for maximum convenience of operation.

Servo Motor Drive High Production Speed! High Accuracy! Veneer infeed → Thickness inspection → Select material cutting → Glue spreading → Veneer composing → Cut to size → Automatic product stacking.

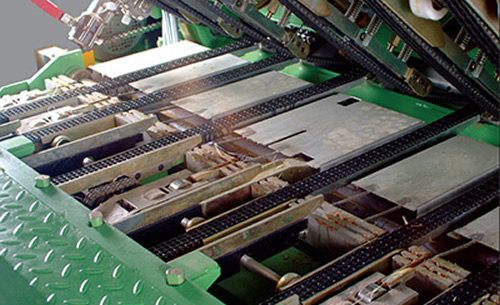

The rear feed system is driven by a high performance servo motor, featuring fast start and stop controls. It also ensures high accuracy cut-to-size.

Eliminate the use of conventional clutch/brake for cutting motion control, the cutting system on NCBS-4F is driven by a high performance servo motor. This not only provides high positioning accuracy, but also extends the knife life.

The front feed system is driven by a high performance servo motor which allows for fast start and stop and high positioning accuracy.

The automatic stacker is ruggedly constructed for outstanding loading resistance without deformation. Core veneers are delivered by a combination of belt and rollers feed system. Powered elevation is driven by a motor.

The core veneer thickness inspection roller is precision machined, and hard chrome plated for superior wear resistance. This combines with high precision thickness inspection device for accurate thickness inspection. Applicable minimum length of core veneer is 80mm.

The specially designed synchronized drives system at top and bottom exhibits highly accurate composing performance for single plate. In addition, it also avoids overlapping of single plates.

The electric control system consists of high quality electronic components, featuring maximum stability of control, long service life and easy maintenance.

The machine motions are controlled by a high performance PLC combined with touch-sensing screen provide user-friendly operation for operator.

| MODEL | VCBS-4F | |

|---|---|---|

| Length of knife | 1350mm | |

| Working veneer width | 968mm to 1270mm (3ft. to 4ft.) | |

| Veneer thickness range | 1.5mm to 4.0mm | |

| Feed speed | 40M/min.(Max.) | |

| Power | Feeding | 2.2kw x 2 sets |

| Glue applicator | 0.4kw | |

| Full-size clipper | 1.5kw | |

| Blower for cooling | 0.75kw | |

| Cooler unit | 460w(AC200V) | |

| Pump for cooler water | 150w(AC200V) | |

| Heater fire hot melt glue | 7.25w(AC200V) | |

| Random Clipper | 2.2kw | |

| Table lift for stacker | 2.2kw | |

| Stacker conveyor | 0.4kwX2sets | |

| Blower for stacker | 0.4kw | |

| Area occupied | 3.2M(W)X12M(L) | |

| Machine weight | N.W.7,500KGS(approx.) | |

| Measurement | 50m2(approx..) | |

Optional Equipment |

||

| Air comperssor | Motor | 3.7KW |

| Air pressure | 6kg/cm2 | |

| Air flow | 60L/min | |

© Copyright Forrich All Rights Reserved. Design by CYnet